Omega Seals

Detailed Data

Detailed Data

The Omega Seal is a good choice for the most demanding high pressure gas or liquid applications. The Omega Seal is also a good choice for vacuum seals.

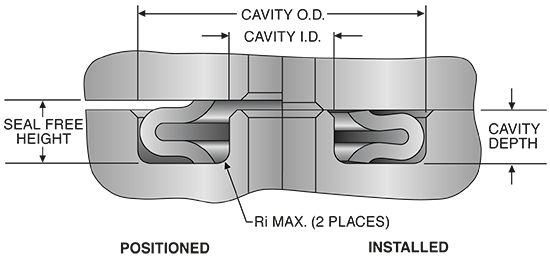

Our Omega Seal offers the lowest leakage rate of all seals available, and is an optimal solution for applications that remain undisturbed for long periods. It's knife-edge seal contact feature concentrates load force to create an effective seal. A deformable coating material on the seal flows into surface grooves and asperities better than any other seal. Precision manufacturing carefully controls wall thickness and end profile for efficient sealing, while coatings increase the seal's effectiveness.

JETSEAL is one of the world's leading manufacturers of Omega Seals.

Omega Seals:

- Are suited to extreme automotive, aircraft and space environments.

- Resist corrosion.

- Come in thin-wall, low-load and non-circular designs.

- Accommodate coatings and plating for improved performance in liquid and gas applications.

- Handle temperatures from cryogenic to 1350°F (732°C).

- Work well for turbine engine case joints, duct-to-case flanges, hydraulic and pneumatic fittings, oil drilling equipment, vacuum components and systems, and cryogenic components and systems.

Operating Conditions:

- Operating pressure range:.............Vacuum (1E-10 torr.) to 36,000 psi

- Functional temperature range:.......Cryogenic to 1350°F (732°C)

- Typical leakage rate:......................1E-7 sccs He/mm circ.

Metallic Options:

- Alloy 718 (AMS 5596, 5589, 5662)

- Alloy X-750 (AMS 5598, 5582, 5667)

- Waspaloy (AMS 5544, 5706, 5586, 5708)

Plating/Coating Options:

- Silver (AMS 2410, 2411)

- Nickel (AMS 2403, 2424,QQ-N-290)

- Gold (Mil-G-45204)

- Copper (AMS 2418)

- PTFE (AMS 2515)

- Lead/Indium

- Other plating options are available

Please call for pricing and availability or fill out the Application Data Sheet (PDF) and Quote Request Form.

Application Data Sheets are available in Spanish, French, German, Russian, Korean, Chinese, Japanese, Farsi,

and Hebrew from JETSEAL's Downloads or Contact Us page.